Polymer

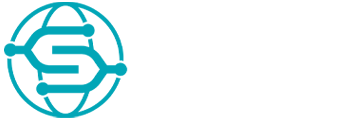

FRP/PP-FRP

Storage Tanks

Suyara Industries is one the leading manufacturer and supplier of high quality FRP Storage tanks offering tanks in polyester general resin, Bisphenol, Isophthalic and Vinyl ester accordingly to the applications and needs.

We offer storage tanks in a variety of configurations and dimensions as per requirements of the customer in Vertical Cylindrical, Horizontal Cylindrical, square and rectangular shapes. Together with this we provide options of flat top and bottom, dished top and bottom and conical top and bottom providing flexibility as per the process requirements.

We fabricate FRP/PP-FRP storage tanks with capacities ranging from 0.1 KL to 80 KL. Our use of high quality raw materials with comprehensive engineering, design and manufacturing done by our skilled workforce ensures that each tank that is manufactured is of highest quality ensuring that it is strong, durable, leak proof, build to last and reliable. We customize nozzles and manholes as per the requirements of the customer with offerings of level Indicator, ladder- monkey cage, railing, valves etc.

FRP storage tanks are light, strong and sturdy, have good dielectric properties, offer excellent resistance to corrosion and no effect to attack of acids/alkali and many other hazardous chemicals. FRP tanks are cost effective, maintenance free and have long life.

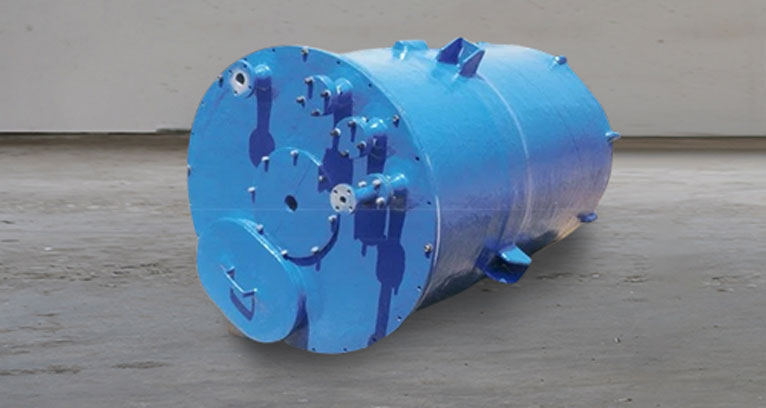

Reaction Vessels

PP-FRP reaction vessels are specialised vessels used for a wide range of industrial applications due to the unique properties offered by them. One of the key advantages of FRP vessels is it corrosion resistance and robust nature making them well suited for chemical processing. The fibres in the composite material offer strength and secureness allowing to withstand temperatures and pressures offering excellent durability. FRP reaction vessels are light weight and compact thus making them easy to install and transport.

We offer FRP reaction vessels in a variety of sizes and capacities with conical/flat/dished bottoms and tops according to requirements of the customers. Based on the chemical, temperature and pressure reaction conditions, we guide to select the right glass fibre and resins with the options- Bisphenol/ GP resin/ Vinyl esters/Isophthalic each having unique properties and cost effectiveness. Our experienced engineering team guides customers in providing the right economical solutions for designing of reaction vessels.

We provide complete reaction/mixing vessel assembly which includes MS framework to support the vessel and top assembly, motor-gearbox, bearing housing, gland-box, agitator, heating/cooling coils and other accessories as per the customer requirements.

Scrubbing Systems

We at SIPL design and manufacture high performance scrubbing systems in FRP/PP-FRP that let you control the air pollution by eliminating/absorbing the acidic/toxic fumes like H2SO4, HCL, HBr, NH3, Cl2, SOx HF, Br, NOx, H2S etc and fine particles from the flue gas streams.

We supply high quality scrubber systems in FRP/PP-FRP as per the customer process requirements and needs using premium grade raw materials with fabrication done by skilled and experienced workforce offering accuracy and efficacy.

We offer complete solution scrubbers systems including tank, scrubber column, inlet outlet nozzles as per design, demister pad, pall rings, pump, circulation lines, distributors and other accessories with complete ducting systems as per process requirements.

Our scrubbers are known for efficient scrubbing offering high performance, low maintenance, easy cleaning, zero-leakage, long exceptional life and easy repair.

Blowers

PP-FRP centrifugal blowers are electromechanical devices widely used in chemical industries that effectively and efficiently generate and improve airflow for exhausting/transporting the flue gases, pollutants, dust particles, gas streams from the processes.

The PP-FRP blowers offered by us come with unbeatable performance and quality with good corrosion and abrasion resistance. PP-FRP blowers are light weight, consume less power, have reduced mechanical noise, good durability, longer life span and are cost effective.

Our offered PP-FRP blowers come with PP/FRP impellers, PP-FRP casing, flanged inlet and outlets, steel shaft, bearings and metal bases that are FRP coated for corrosion resistance. In our offered blowers material contact parts are all in PP and FRP making the blower to be resistance to corrosion.

FRP/MS-FRP Linned Nutsche Filter

We supply strong and durable customized efficient wide range of PP-FRP and FRP coated MS Nutsche Filter as per customer requirements. Our robust design makes them to efficiently filter solutions/slurries speeding up the filtration process with the use of vacuum.

Our Nutsche filters are appreciated for high strength, optimal performance and long lasting owing to our precision engineering, use of right good quality raw materials with fabrication done by our skilled and experienced workforce. We offer complete Nutsche filter systems with main shell, thick PP/HDPE perforated plate with strong bottom supports, inlet outlet nozzles and hand holes, lifting arrangements etc. as per the customer requirements.

We supply cost effective FRP lined MS Nutsche filters providing excellent efficacy and strength with the complete FRP Lining skilfully done to the MS structure providing it resistance to corrosion and chemical attacks.

Receivers

In line with the client’s wide basket of requirements, we bring forth a impeccable range of optimum quality FRP/PPFRP receiver tanks that find good economical applications in chemical process industries.

FRP/PP-FRP receivers are light weight, strong, abrasion and corrosion resistant, cost effective, less maintenance and durable making them widely used in chemical process industries.

We offer customized receivers of various sizes, capacities and dimensions with our designs incorporating MS stiffing rings and supports offering the receivers extra strength capacitated to withstand full vacuum with long reliable functional life.

Ducting Systems

PP-FRP/FRP Ducting is widely taken into use in the Research and Development Centres, Laboratories, Exhaust Systems, and Chemical Industries owing to their corrosion resistance, light weight, durability, less maintenance and good mechanical strengths.

We design and manufacture various sizes of PP-FRP/FRP ducting, piping systems to carry corrosive and toxic gases like H2SO4, HCL, HBr, NH3, Cl2, SOx HF, Br, NOx, H2S, solvent etc. SIPL offers complete industrial ducting systems in FRP/PP-FRP in circular/square/rectangular shapes of various dimensions and diameters as per the process requirements/customer requirements. Along with straight ducts, we very accurately design fabricate bend ducts of all angles even for ducting in complex area according to the requirements.

Our ducts are mechanically very strong and robust thus withstanding pressures and vacuum. SIPL ducting systems are recognized to be leak proof, strong, long functional life and having zero maintenance. Along with design and manufacture we undertake to provide complete on site installation of the ducting systems with saddles supports.

Customised Products

We with us the of optimum grade resins- polyester general resin, Bisphenol, Isophthalic and Vinyl ester, robust experienced design and engineering team and skilled fabrication teams offer wide range of customized products and services. Some of the customised products we offer are:

- Open top containers

- Trays

- Hopper

- Motor covers

- Centrifuge/FBD tray/nustche filter top covers

- Addition and Collection Pots

- Cooling Tower

- FRP lined agitators

- Damper valves

- Chlorine Cylinder Hood

On site FRP lining to MS structures

We provide on-site services of FRP lining to various MS structures prone in an environment to corrosion, pitting and chemical attacks. We provide various resin FRP linings such as GP resin, Isophthalic, Bisphenol and Vinyl esters per the conditions and requirements so as to prevent corrosion/damage to the MS structures such as MS columns/beams, platforms, ladders, railing, underground/over the ground MS tanks, ETP tanks etc to increase its service life and reduce it maintenance.

Material of Construction

-

Thermoplastic:

- a) Virgin Poly Propylene

-

Resins:

- a) Polyester

- b) Vinyl Ester

- c) Epoxy

- d) Phenolic Formaldehyde

PP-FRP, PP Welding & Design Standard

-

DVS 2207-1:

For Butt & Fusion Welding & Fabrication of Thermoplastics -

BS 4994 : 1987:

Specification for Design and Construction of Vessels and Tanks in Reinforced Plastics -

BS EN 13121:

GRP Tanks and Vessels for use above ground, Raw Materials, Specification conditions and Acceptance conditions

-

ASTM D 3299:81:

Standard Specification for Filament-Wound Glass-Fiber-Reinforced Thermoset Resin Corrosion-Resistant Tanks -

ASTM Section X:

It is a relatively new part of the International Boiler and Pressure Vessel Code providing methods for Designing, Building, Inspecting and Testing Fibre-Reinforced Plastic (FRP) Pressure vessels.