HDPE/PP

Storage Tanks

We design and fabricate premium quality PP/HDPE storage tanks using high quality raw materials with fabrication done using German make tools and welding machines. We offer storage tanks in various sizes and configurations such as vertical cylindrical and horizontal cylindrical, square and rectangular shapes & sizes with customized options as per the customer needs.

We offer storage tanks from capacities 0.1KL to 100KL with customized inlet-outlet nozzles, manholes, level indicators, railing, monkey cage-ladder and other accessories as per the customer requirements.

We offer tanks in 2 technologies – unique spiral winding technology and Butt fusion technology using imported automatic butt fusion machine.

Suyara offered Storage tanks are appreciated for robust design, accurate dimensions, client process – friendly solution, leak proof, maintenance free, exceptional storage performance and long service life.

Key Features

- Light Weight, easy to install and move

- Durable

- Non-Corrosive

- Abrasion Resistance

- High resistance to various chemicals/solvents and toxic elements

- Easy repair

- Strong and Sturdy

- HDPE tanks can withstand temperatures up to 60o C and PP tanks can withstand temperatures up to 100o C

- Low Cost/Litre compared to other MOC’s

Key Features

- Light Weight, easy to install and move

- Durable

- Non-Corrosive

- Abrasion Resistance

- High resistance to various chemicals/solvents and toxic elements

- Easy repair

- Strong and Sturdy

- HDPE tanks can withstand temperatures up to 60o C and PP tanks can withstand temperatures up to 100o C

- Low Cost/Litre compared to other MOC’s

Reaction Vessels

We offer process friendly design and customer-solution oriented reaction vessels in PP and HDPE. One of the key advantages of PP/HDPE vessels is it corrosion resistance and robust nature making them well suited for chemical processing involving acids and alkalis.

We fabricate reactors using premium grade raw materials using high precision tools and machineries. We offer FRP reaction vessels in a range capacities from 0.5KL to 20KL with conical/flat/dish bottom and top with PBT/anchor agitator according to requirements of the customers.

We provide complete reaction/mixing vessel assembly which includes MS framework to support the vessel and its upper assembly , motor-gearbox, bearing housing, gland-box, agitator, heating/cooling coils and other accessories as per the customer requirements.

Suyara PP/HPDE reaction vessels are recognized for providing process oriented-solution designed reaction vessels, leak proof, low maintenance, exceptional performance and long functional life.

Key Features

- Light weight, easy to install and move

- High resistance to chemicals and solvents

- Durable

- Corrosion Resistance

- HDPE reaction vessels can withstand temperatures up to 60o C and PP reaction vessels can withstand temperatures up to 100o C

- Low cost compared to other MOC for similar application

Key Features

- Light weight, easy to install and move

- High resistance to chemicals and solvents

- Durable

- Corrosion Resistance

- HDPE reaction vessels can withstand temperatures up to 60o C and PP reaction vessels can withstand temperatures up to 100o C

- Low cost compared to other MOC for similar application

Scrubber

We at SIPL offer high performance scrubbing systems in PP and HDPE that let you control the air pollution by eliminating/absorbing the acidic/toxic fumes from the exhaust streams from the processes in tandem to the universally accepted norms.

We supply efficiently designed quality scrubber systems in PP and HDPE as per the customer process requirements and needs using premium grade raw materials with fabrication done using imported make tools and machineries offering accuracy and efficacy.

We offer complete solution scrubbers systems including tank, scrubber column, inlet outlet nozzles as per design, demister pad, pall rings, pump, circulation lines, distributors and other accessories with complete ducting systems as per process requirements.

Our scrubbers are known for efficient scrubbing offering high performance, low maintenance, easy cleaning, zero-leakage, long exceptional life and easy repair.

Key Features

- Light weight, easy to install and move

- Highly effective in scrubbing H2SO4, HCL, HBr, HF, Br2, NH3, Cl2, SOx, NOx, H2S and other toxic fumes

- Good resistance to chemicals and solvents

- Corrosion Resistance

- High strength

- Convenient Handling

Key Features

- Light weight, easy to install and move

- Highly effective in scrubbing H2SO4, HCL, HBr, HF, Br2, NH3, Cl2, SOx, NOx, H2S and other toxic fumes

- Good resistance to chemicals and solvents

- Corrosion Resistance

- High strength

- Convenient Handling

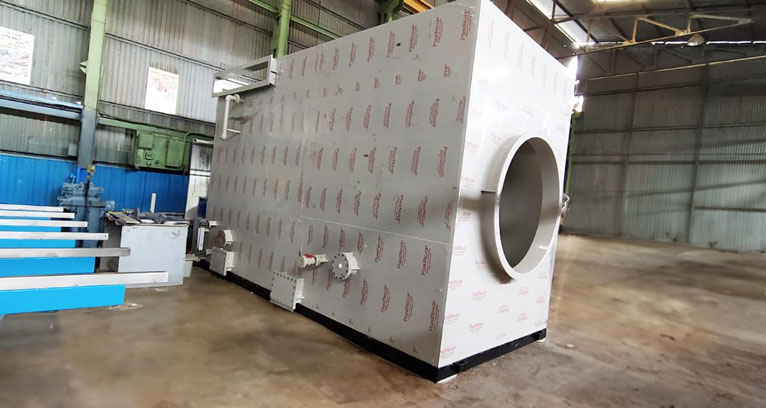

Ducting Systems

We design and manufacture various sizes of ducting, piping systems to carry corrosive and toxic gases like H2SO4, HCL, HBr, NH3, Cl2, SOx HF, Br, NOx, H2S, solvent etc. SIPL offers complete industrial ducting systems in PP and HDPE in circular/square/rectangular shapes of various dimensions and diameters as per the process requirements from the process output to the scrubber systems or as per the customer requirements. Along with straight ducts, we also very accurately fabricate ducts of all angles according to the requirements.

Our ducts are mechanically very strong and robust thus withstanding pressures and vacuum. SIPL ducting systems are recognized to be leak proof, strong, long functional life and having zero maintenance. Along with design and manufacture we undertake to provide complete on site installation of the ducting systems with saddles supports.

Key Features

- Light weight

- Smooth inner surface enabling good circulation

- Easy repairs

- High strength

- Good thermal insulation

- Non corrosive

- Low thermal conductivity and non-sparking

Some of the customised products we offer are

Key Features

- Light weight

- Smooth inner surface enabling good circulation

- Easy repairs

- High strength

- Good thermal insulation

- Non corrosive

- Low thermal conductivity and non-sparking

Pickling Tanks

Pickling tanks are tanks that are used for metal surface treatment where the metal is immersed in the pickling acid in the tank in order to remove/scale off the rust/oxides/impurities/stains from the material being treated.

We offer wide range of pre-treatment and post treatment pickling tanks in PP and HDPE in different shapes and capacities as per the customer process requirements and needs. We fabricate the tanks using imported bending, welding and rolling butt fusion machine for fabricating the main body and the end walls which offer seamless surface thus eliminating the risks of leakages and tank failures.

Our pickling tanks are made from high quality virgin material PP/HDPE sheets with welding done using German make tools and machineries. With the pickling tanks we provide strong MS support structures with lifting arrangements that are PP cladded or FRP coated to resist acid attack.

Our pickling tanks are recognized for robust construction, zero maintenance, big life span, leak proof, good weld joints and strong and sturdy.

Key Features

- Easy to repair

- Acid/Alkali/Chemicals resistant

- Low cost

- Non-corrosive

- Abrasion resistance

- Durable

Key Features

- Easy to repair

- Acid/Alkali/Chemicals resistant

- Low cost

- Non-corrosive

- Abrasion resistance

- Durable

Nutsche Filter

We supply premium quality made customized efficient Nutsche Filter in PP/HDPE as per customer requirements and needs. Our robust design makes them to efficiently filter solutions/slurries withstanding vacuum making its use easy and convenient.

We fabricate using good quality raw materials with welding done using German make tools and machineries offering accuracy and efficacy. We offer complete Nutsche filter systems with main shell, thick PP/HDPE perforated with strong bottom supports, inlet outlet nozzles and hand holes, lifting arrangements etc.

Our PP/HDPE Nutsche filters as recognized for robust design, easy use, strong and sturdy, less maintenance, leak proof and cost effective.

Key Features

- Light weight, easy to install and move

- Easy to repair

- Acid/Alkali/Chemicals resistant

- Non corrosive

- Abrasion resistant

- HDPE nutsche filters can withstand temperatures up to 60o C and PP nutsche filters can withstand temperatures up to 80o C

Key Features

- Light weight, easy to install and move

- Easy to repair

- Acid/Alkali/Chemicals resistant

- Non corrosive

- Abrasion resistant

- HDPE nutsche filters can withstand temperatures up to 60o C and PP nutsche filters can withstand temperatures up to 80o C

Receivers

We design and manufacture wide capacities of receivers in HDPE and PP according to the dimensions and specifications of the customer requirements.

We fabricate using good quality virgin raw materials with welding done using imported make tools and machineries making the receivers leak proof, strong and offering zero maintenance.

Our robust design offers the receivers to be strong and sturdy capacitated to withstand temperature, pressure and vacuum with the offering of long reliable functional life.

Key Features

- Light weight, easy to install and move

- Abrasion resistant

- Easy repairs

- Corrosion resistant

- Acid/Alkali/Chemicals resistant

- Low Cost

Key Features

- Light weight, easy to install and move

- Abrasion resistant

- Easy repairs

- Corrosion resistant

- Acid/Alkali/Chemicals resistant

- Low Cost

Dosing Tanks

We design and manufacture high quality dosing tanks in PP/HDPE using premium grade raw material with good fabrication quality achieved by our skilled workforce using German make tools and machineries.

With an option with spiral shells we also fabricate the main body from plain sheets using imported bending, welding and rolling butt fusion machine offering seamless surface thus eliminating the risks of leakages and tank failures.

We offer dosing tanks from capacities 50 litres to 2000 litres in cylindrical/square/rectangular sizes of various dimensions and specifications as per the requirements of the customer. We customize the tanks, their lids, nozzles etc as per the customer requirements and meet the requirements of Pharma industries that require high quality and finish.

SIPL dosing tanks are known for robust design, strength, leak proof, low maintenance, cost effective and long function life.

Key Features

- Light weight, easy to move

- Abrasion resistant

- Easy repairs and maintenance

- Corrosion resistant

- Acid/Alkali/Chemicals resistant

- Strong and Sturdy

- Durable

Key Features

- Light weight, easy to move

- Abrasion resistant

- Easy repairs and maintenance

- Corrosion resistant

- Acid/Alkali/Chemicals resistant

- Strong and Sturdy

- Durable

Customised Products

We with our German make tools and machineries and bending, rolling and welding butt fusion machine offer wide range for customized products in PP and HDPE material of construction of various dimensions and shapes as per the customer requirements. Some of the customised products we offer are:-

- Open top containers

- Trays

- Hopper

- Motor covers

- Centrifuge/FBD tray/nustche filter top covers

- Addition pots

- Collection pots

- PP/HDPE lined agitators

- Damper valves

- Shovel’s/scrappers/scoop

Key Features

- Open top containers

- Trays

- Hopper

- Motor covers

- Centrifuge/FBD tray/nustche filter top covers

- Addition pots

- Collection pots

- PP/HDPE lined agitators

- Damper valves

- Showels/scrappers/scoop

Pipe and Fittings

We offer wide range of PP and HDPE Pipe and fittings:

- Pipes with diameters ranging from 15NB to 250NB

- Stubends

- Flanges

- Blind Flanges

- Tailpieces

- 45Deg and 90 Deg Elbows

- Tees

- Reducer

- Cooling Tower nozzles

- PP Nut bolts

- Valves

- Sight glass

Together with material supply at competitive prices we also provide onsite complete pipeline installation works as per the customer requirements and also offer services of onsite pipeline repairs and maintenance works.

Material of Construction

- Virgin grade of HDPE (PE-100) & Virgin grade of polypropylene copolymer

Design & Welding standards

-

DVS 2205:

Design & calculations for containers and apparatus made from thermoplastic -

DVS 2207:

Welding & Fabrication of thermoplastics

Testing Standards

-

EN 13100-1:2000:

Visual Examination -

EN 13100-2:2004:

X-Ray Radiographic Testing -

EN 13100-3:2004:

Ultrasonic Radiography